Long Steel Processing Specialists

Long Laser and Plasma Cutting, Forming and Welding

At H.W. Metals, long metal processing and fabrication is our specialty. We provide full-service, custom steel processing for parts up to 60’ in length and beyond. By making large-size parts from a single piece of material, rather than welding or otherwise joining two or more smaller pieces, we are able to deliver a better quality product. It also reduces material requirements and reduces or eliminates the need for welding and other joining processes, leading to lower prices and faster turnaround times for our customers.

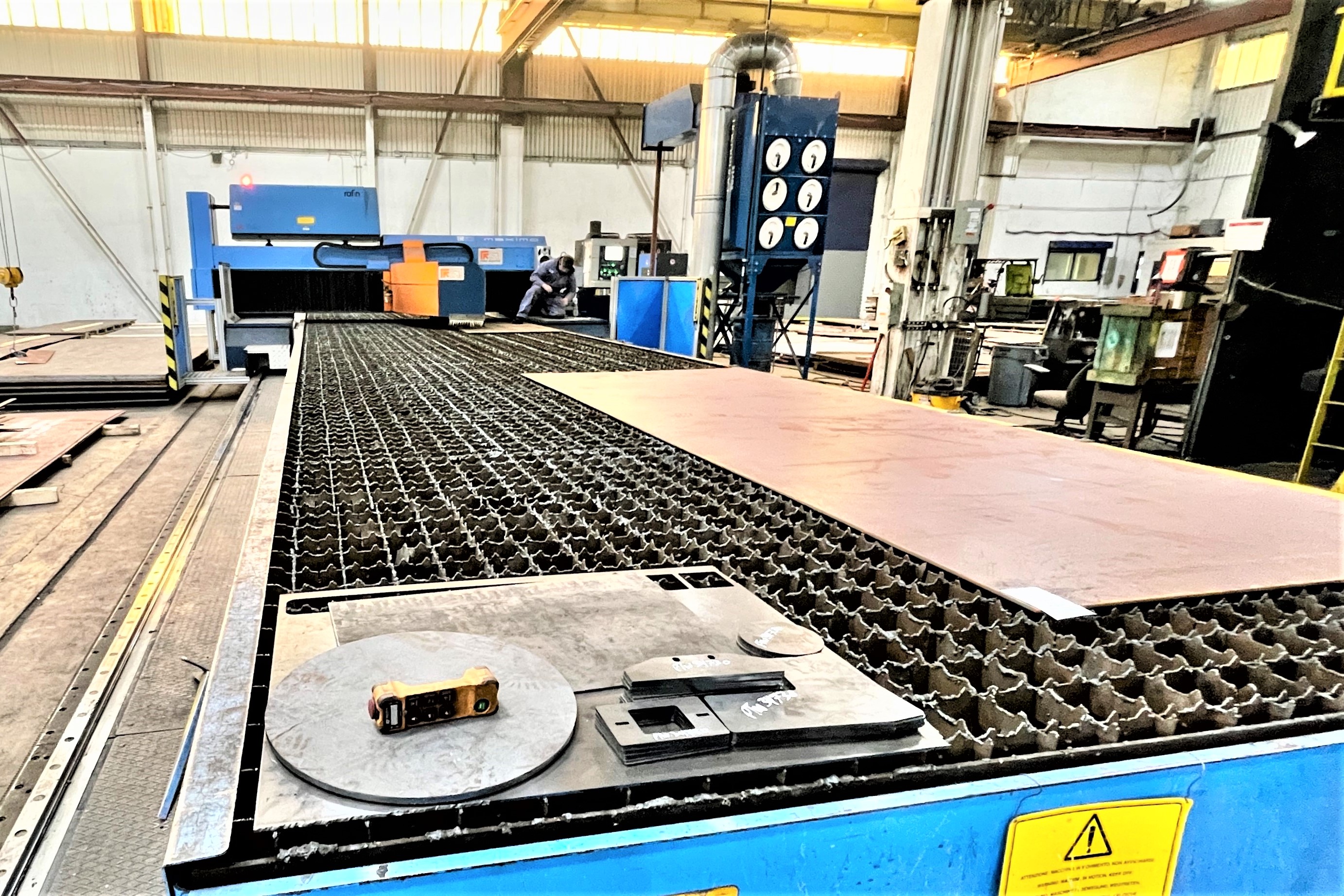

H.W. Metals’ specialized and customized production equipment enables us to form, laser cut, plasma burn, punch, and weld large metal products just as easily as other steel processors produce smaller parts. And, though we specialize in large metal fabrication, we offer the same high quality custom steel processing for parts, components, fabricated products and projects of all sizes.

- Metal Forming Up to 60’ in continuous length, 2500 tons of force and 36” throat depth, one of the largest press brakes in the United States.

- Plasma Cutting Up to100' long worktables, capable of cutting up to 3" thick steel, drilling a 4" hole into a 4 " thick plate and identify parts with a multi-jet inkjet printer.

- Laser Cutting 60’ long worktable, cutting material in thicknesses up to ¾”.

- Welding MIG, Sub Arc and Open Arc Welding, with automated Gantry Welding Systems, capable to fabricate custom steel towers in sizes up to 138” x 138” x 70’ and a 11’ diameter, in continuous lengths up to 60’, longer using splices.

Long Steel Processing Featured Links

For more information on how H.W. Metals can assist you with your long steel processing, follow the links, or give us a call.

H.W. Metals is your #1 domestic outsource option for full-service steel processing of all sizes, specializing in long…